Our Capabilities

We multiply possibilities by investing in people and partnerships. It’s a difference you can feel on the production line and in every product.

Manufacturing

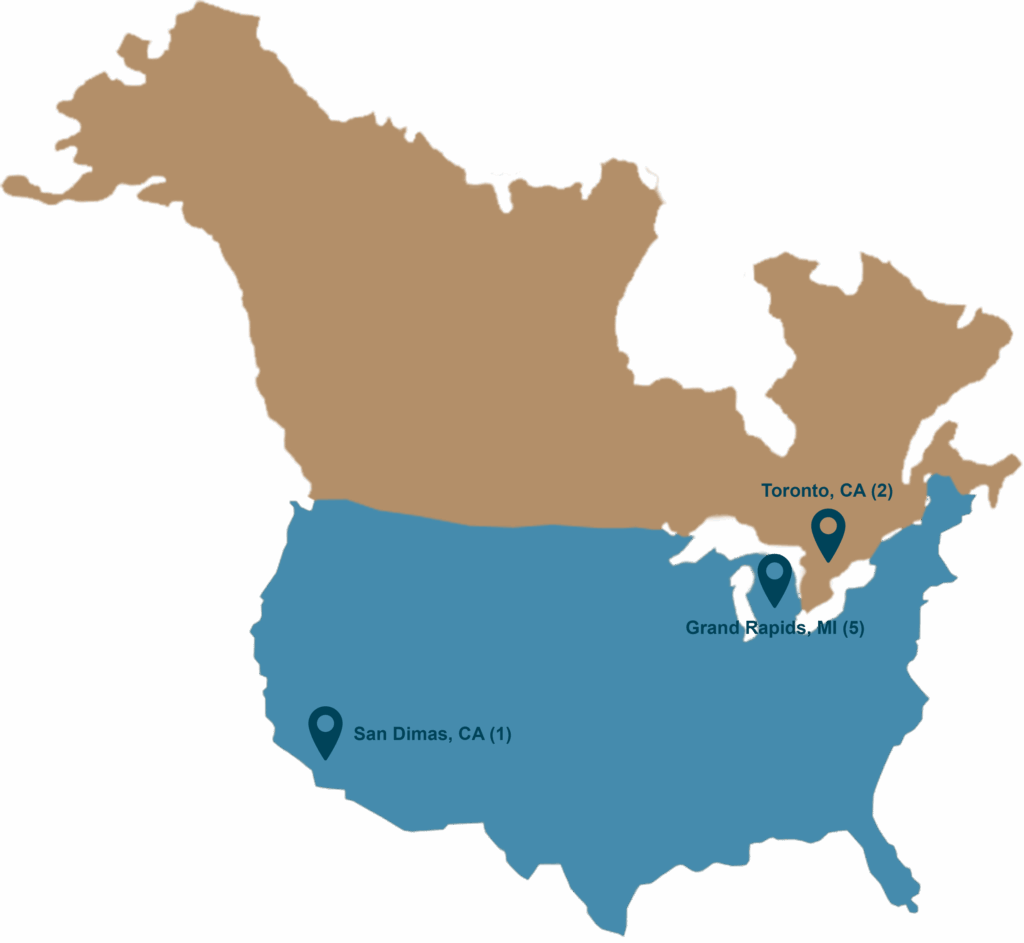

Organic Milling is based in San Dimas, California and is now fully integrated with the broader Roskam Foods manufacturing network. We build long-term partnerships offering transparency, flexibility and exceptional food safety and quality. Our 40,000 sq ft peanut-free facility is SQF-Level III certified, the highest level awarded by the Safe Quality Food Institute, reflecting our commitment and adherence to the highest standards of food safety, quality, and manufacturing excellence.

Our production capabilities include twin-screw extrusion, flaking, coating, multi-component blending, and continuous granola production, allowing us to manufacture almost any product you see in the cereal or granola aisle. Packaging capabilities include bag-in-box and stand-up resealable pouches, bulk cases, and display pallets in a multitude of configurations.

Processing

- Twin-Screw Extrusion

- Direct Expanded Cereal Shapes (e.g., O’s)

- Direct Expanded Crisps (e.g., Rice, Protein)

- Indirect Expanded Cereal (e.g., Flakes)

- Direct Expanded Snacks (e.g., Puffs)

- Flaking

- Drying & Toasting

- Coating

- Multi-Component Blending

- Continuous Granola Production

Packaging

- Carton – Bag in Box

- Dual Pack – Bag in Box

- Stand-Up Resealable Pouch

- Bulk Cases & Supersacks

- Club Promotional Displays

Certifications & Food Safety

We’re committed to building a strong, proactive food safety culture—one that drives regulatory compliance, supports certification excellence, and powers continuous improvement. Our Food Safety & Quality team plays an integral role throughout product development to ensure we meet the highest standards at every step.

Research & Development

Our Research & Development team brings deep experience and a passion for making the impossible possible. Whether it’s crafting new flavors, refining ingredient costs, or developing standout formulations, we create products rooted in consumer insight, built for your brand, and ready to scale. From first idea to full production, we’re with you every step of the way.

- Ideation

- New Product Development

- Sensory Evaluation

- Shelf-Life Evaluation

- Plant Trials & Testing

- Specification Development

- Regulatory Compliance

- Commercialization

- Product Optimization

- Project Management

- Troubleshooting

Engineering

As a strategic partner, our Engineering team leads product and packaging development through feasibility, testing, and implementation. With broad technical expertise and close collaboration, we design solutions that support growth while optimizing performance.

- Feasibility Studies

- Capital Assessments

- Line Designs

- Line Modifications

- Plant Trials

- Commercialization

- Packaging Development

- Specification Development

- Cost Savings Initiatives

- Capital Project

Management & Execution - Troubleshooting

Supply Chain

With full EDI capabilities and modern systems, we offer an end-to-end view of your supply chain. From sourcing through delivery, we operate as an extension of your team – delivering reliable supply and building trust every step of the way.

- Material Sourcing

- Demand Planning

- Supply Planning

- Capacity Planning

- Scheduling

- Allergen controlled warehousing

- Multi-temp storage

and distribution - Logistics

Project Management

From concept through commercialization, we sweat all the details, so you don’t have to. We offer dedicated project management support on every project and partner with you every step of the way to ensure seamless coordination, clear communication, and efficient and successful project delivery. We earn our customers’ trust and loyalty by consistently executing projects with excellence, speed, responsiveness and professionalism.